Once your artwork is printed and looking sharp as a razor, you may want to think about how you bring it all together – let’s get binding!

There are a number of styles and processes used to bind artwork. Here we touch on a few most commonly used methods with the main benefits of each. These are also covered in our Ultimate guide to print so if you’d like a more in depth look at printing processes as a whole then feel free to download it here. COMING SOON.

Perfect Binding uses Ethylene Vinyl Acetate (EVA) to glue pages together and create a spine with a squared off back. Paper back novels and magazines often use perfect binding.

PUR Binding is regularly used for documents with many pages or artwork designed on a heavier paper weight or when more ink is used, such magazines or books. The process uses polyurethane reactive (PUR) adhesives to bind the paper together and is extremely good at maintaining its hold even after repeated usage. The process tends to better withstand extreme temperatures and is less likely to crack when the book is laid flat - it is approximately 60% stronger than perfect binding, which is why we regularly recommend this option to our clients.

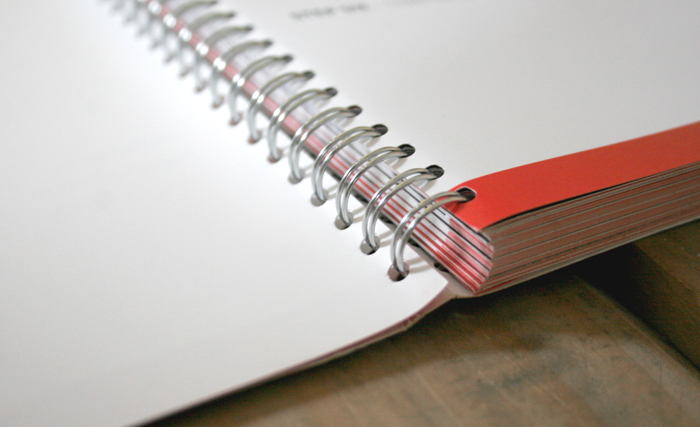

Wiro / Spiral: A great option for note pads and business documents. This offers a professional bind and at relatively low cost. The process involves inserting a metal spiral wire binding strip into punched out holes to secure each page together. This option has the added benefit of allowing the document to lie completely flat which is why it is often used in office stationery.

Saddle Stitch is a quick and effective method of binding often used to bind smaller documents. It uses wire staples or stitches through the centrefold and spine of the document.