Behind the scenes - Press Pass

30th July, 2013

We have recently produced this year's copy of 'The Oratorian', an annual publication distributed to parents and children attending The London Oratory School. We have managed this job for many years including the design, typesetting, and print and arranging delivery to London This job always has very tight deadlines and is a complex piece which requires substantial project management.

Below is an overview of what was involved in the press pass for this job.

Each time the job is produced, we obtain prints of the cover and inner pages prior to going to press to check for quality and colour reproduction. When the job is ready to go to print, we will press pass ensuring that the final printed job meets with the client's exacting standards. A press pass is a cost-effective way of checking for colour and quality issues, as picking up on details at this late stage can save a substantial amount of time and money.

Firstly we viewed the cover and adjusted the colour levels. The levels of red were increased to bring out the burgundy colour on the Junior House blazers. This produced a lovely rich colour for the picture on the cover.

We were able to adjust the colours of the cover

We used a selection of previous issues to compare with the new press copies to ensure quality continuity. The process was repeated with a selection of inner pages, where we also checked the previous press proofs for comparison. At this point an issue was raised regarding the depth of black on the inner pages. These areas were very grey and mottled in spite of the fact that it was to be printed on identical stock as previous issues.

To rectify this we changed the paper type for a slightly glossier stock which produced the depth of black that we required.

Showing the difference in finish using a different paper stock

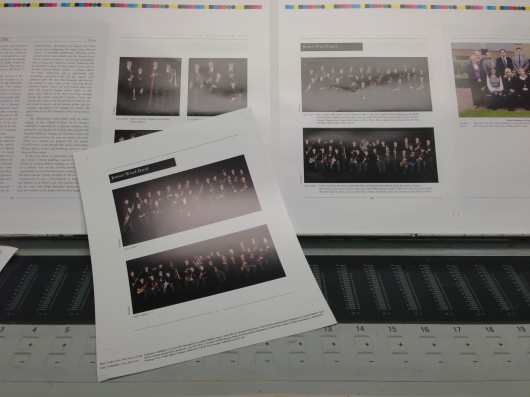

The Oratorian contains many group images, which need to be as clear as possible. At a press pass, we were able to manipulate the images prior to printing to obtain the desired result.

Comparing the press proof with print outs on the press

Once the entire print and collating part of the job was complete, the next step was to see the finishing machines in action.

Collated copies ready to be bound and trimmed

The finishing machine folds the imposed artwork into pages ready to be bound and trimmed.

This is a great opportunity to further assess the quality of the print in it's almost final stages.

Checking the print quality, using a previous edition for reference.

Overall, the press pass was incredibly useful. Seeing the printed artwork we were able to check the quality of finish and this led to altering the paper stock and amending colour levels to enhance the images. As we were able to make these decisions then and there the changes made didn't delay production in spite of an incredibly tight deadline.

Comments

comments powered by Disqus